A bit of a rant:

I've worked in the bicycle industry for a bit now- long enough to still remember the start of the LBS vs. on-line dealer wars and the time when Superblo was buying up shops to kill any meaningful difference. I believed then, and still do, that people are willing to (and should expect to) pay more for a "pro" shop experience that includes educated, experience based guidance, quality and timely repair or service work, clean bathrooms and a generally appreciative staff atmosphere. I don't think the customer is always right, but I do think they should be treated with respect and appreciation.

As a customer, I am not a big fan of paying retail- at least not for things that are mass produced and sold through international distribution channels. Fortunately, as an industry insider, I have many options on that front. That said, I am a huge fan of supporting local independent buisness and try to buy small things from local shops if I can (like tubes, chain lube, etc.). Sure, I'm not sending anybodies kids to college, but I try to help keep a viable community. But I'm also not willing to take abuse for the "privilege".

Friday I stopped by a local shop to pick up some vinyl for some down tube decal samples, and noticed a little shop I had always heard about and wanted to check out. I had a few bucks in my pocket and my wife needs a new helmet cover, so why not?

Hmmm... its never a good sign when you have to search for the bike rack in front of a store...

I checked the sign on the door and noted that I had 15 minutes before they closed. Plenty of time to do a quick lap, grab a helmet cover and groove on local bike shop vibes. Nope. I walked in and instantly got the stink eye. I smiled and walked over to the gloves. In one quick breath I heard th woman at the counter say:

"Hiyouknowwe'reclosingnow"

Um...ok...

The tone and attitude are impossible to type, but she literally stopped me in my tracks. My cockles went up and the pissey East Coast "screw you" meter went to 11. I turned on my heels and started to leave. As if some little tiny dollar signs started to die in her eyes, she quickly yelled after "hey, did you need anything?".

Yeah- decent customer service.

Rant off- thanks for that!

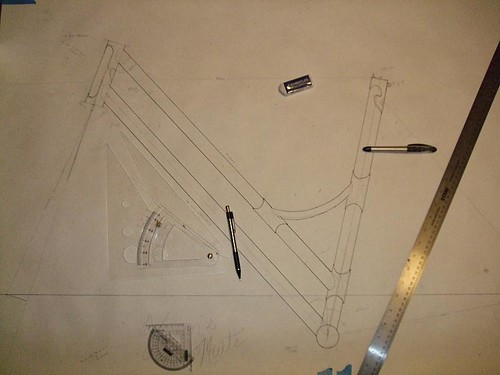

I finished cleaning up the fillets on the track bike, but the lighting was to far off today to get any decent shots. I'll try to get a raw pic before she gets shot with powder (I have a cool triple color scheme coming for this one)!